Elastomer Hoses

Low pressure hoses, silicone hoses, distribution of non-braided hoses

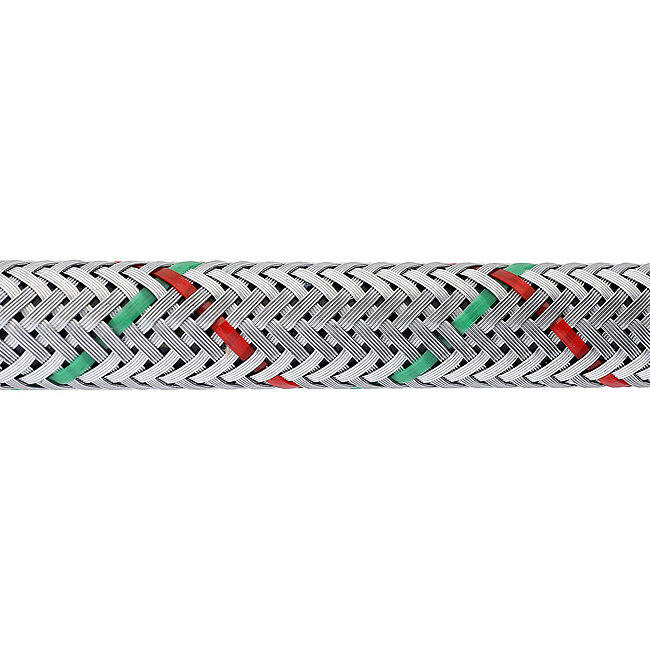

We perform hose braiding according to our in-house standards or customer specifications. The primary materials used are galvanized steelwire or stainless steel wire.

With sufficient volume, color markings and coil lengths different from the standard are possible.

Low-pressure hose

Description

Low-pressure hose with single layer braiding

Hose construction

Inner layer: NBR/PVC machine hose (DIN EN ISO 6806)

1st layer: galvanised-iron wire or 1.4301 stainless-steel wire

Temperature range

Depending on the medium, -35 °C to +80 °C

| Reference | ID | Wall Thickness | Burst pressure min. | Bending radius min. | Coil length approx. | Weight approx. |

|---|---|---|---|---|---|---|

| 16052 | 3,5 mm | 2,0 mm | 60 bar | 20 mm | 100 m | 0,098 kg/m |

| 16053 | 3,8 mm | 1,0 mm | 30 bar | 20 mm | 100 m | 0,058 kg/m |

| 16055 | 4,5 mm | 2,0 mm | 60 bar | 25 mm | 100 m | 0,100 kg/m |

| 16057 | 5,1 mm | 2,0 mm | 60 bar | 25 mm | 100 m | 0,130 kg/m |

| 16059 | 6,0 mm | 2,0 mm | 60 bar | 25 mm | 100 m | 0,122 kg/m |

| 14765 | 7,0 mm | 1,6 mm | 45 bar | 25 mm | 100 m | 0,145 kg/m |

| 16060 | 7,5 mm | 2,0 mm | 50 bar | 30 mm | 100 m | 0,147 kg/m |

| 16062 | 7,7 mm | 2,0 mm | 50 bar | 30 mm | 100 m | 0,166 kg/m |

| 16051 | 8,8 mm | 2,0 mm | 50 bar | 40 mm | 100 m | 0,185 kg/m |

| 16064 | 9,3 mm | 2,0 mm | 50 bar | 40 mm | 100 m | 0,179 kg/m |

| 16065 | 11,4 mm | 2,5 mm | 50 bar | 50 mm | 100 m | 0,243 kg/m |

| 16066 | 12,9 mm | 2,5 mm | 50 bar | 60 mm | 40 m | 0,295 kg/m |

| 16067 | 14,4 mm | 3,0 mm | 50 bar | 70 mm | 50 m | 0,416 kg/m |

| 16068 | 17,0 mm | 3,5 mm | 50 bar | 100 mm | 40 m | 0,428 kg/m |

| 16069 | 21,4 mm | 4,0 mm | 50 bar | 120 mm | 30 m | 0,572 kg/m |

| 16070 | 24,8 mm | 4,0 mm | 40 bar | 150 mm | 30 m | 0,774 kg/m |

| 16071 | 30,0 mm | 5,0 mm | 30 bar | 250 mm | 20 m | 1,125 kg/m |

| 16072 | 38,0 mm | 5,0 mm | 30 bar | 300 mm | 10 m | 1,438 kg/m |

Delivery programme and datasheet

Dateigröße: 45 KB

Low pressure hose

Silicon hoses

Our silicone hoses offer excellent physical properties for a wide range of applications in the food and pharmaceutical industry, medical technology, water supply, and sanitation. The hoses are cold-flexible down to -60°C and temperature-resistant up to +200°C in dry heat.

With the braiding made of stainless steel wire, the hoses are perfectly suited for low-pressure applications. They are resistant to aging, weather, ozone, UV, and many other chemicals.

| Reference | ID | OD | Burst pressure min. | Bending radius min. | Coil length approx. | Weight approx. |

|---|---|---|---|---|---|---|

| 20145 | 3,4 ±0,2 mm | 8,2 ±0,3 mm | 60 bar | 25 mm | 100 m | 0,080 kg/m |

| 20146 | 4,2 ±0,3 mm | 9,3 ±0,3 mm | 60 bar | 25 mm | 100 m | 0,095 kg/m |

| 20147 | 5,5 ±0,3 mm | 10,3 ±0,4 mm | 60 bar | 25 mm | 100 m | 0,116 kg/m |

| 20148 | 5,9 ±0,3 mm | 10,8 ±0,4 mm | 50 bar | 30 mm | 100 m | 0,126 kg/m |

| 20149 | 7,3 ±0,3 mm | 12,3 ±0,4 mm | 50 bar | 30 mm | 100 m | 0,150 kg/m |

| 20150 | 7,7 ±0,3 mm | 12,5 ±0,4 mm | 50 bar | 35 mm | 100 m | 0,154 kg/m |

| 20151 | 9,0 ±0,3 mm | 13,7 ±0,4 mm | 50 bar | 40 mm | 100 m | 0,174 kg/m |

| 20152 | 9,5 ±0,3 mm | 14,0 ±0,4 mm | 50 bar | 40 mm | 100 m | 0,182 kg/m |

| 20153 | 11,0 ±0,4 mm | 16,9 ±0,5 mm | 50 bar | 45 mm | 50 m | 0,246 kg/m |

| 20154 | 12,2 ±0,4 mm | 18,6 ±0,5 mm | 50 bar | 55 mm | 50 m | 0,288 kg/m |

| 20155 | 14,4 ±0,4 mm | 21,4 ±0,6 mm | 50 bar | 60 mm | 50 m | 0,337 kg/m |

| 20156 | 17,4 ±0,5 mm | 25,0 ±0,6 mm | 50 bar | 70 mm | 50 m | 0,446 kg/m |

| 20157 | 21,8 ±0,6 mm | 29,8 ±0,7 mm | 50 bar | 90 mm | 50 m | 0,597 kg/m |

| 20158 | 25,0 ±0,6 mm | 33,6 ±1,0 mm | 40 bar | 150 mm | 25 m | 0,667 kg/m |

| 20159 | 31,3 ±1,5 mm | 41,9 ±1,5 mm | 30 bar | 200 mm | 25 m | 1,046 kg/m |

| 20160 | 40,0 ±1,5 mm | 52,3 ±1,5 mm | 10 bar | 205 mm | 25 m | 1,382 kg/m |

Delivery programme and datasheet

Dateigröße: 177 KB

Silicon hose

Distribution of non-braided hoses

Rubber hoses have been part of our product range for over 60 years. They are also available as commercial products without braiding. You can find a list of available dimensions here:

| Reference | Dimension | Tolerance ID | Tolerance Wall thickness | Coil length approx. | Weight approx. |

|---|---|---|---|---|---|

| 16125 | 3,5 x 2,0 | ±0,2 mm | ±0,2 mm | 100 m | 0,046 kg/m |

| 19910 | 4,2 x 1,0 | ±0,2 mm | ±0,2 mm | 100 up to 1 000 m | 0,038 kg/m |

| 20050 | 4,2 x 1,5 | ±0,2 mm | ±0,3 mm | 100 up to 1 000 m | 0,058 kg/m |

| 10183 | 4,5 x 2,0 | ±0,3 mm | ±0,3 mm | 100 m | 0,059 kg/m |

| 10186 | 4,8 x 2,0 | ±0,3 mm | ±0,3 mm | 100 m | 0,081 kg/m |

| 10187 | 5,5 x 2,0 | ±0,3 mm | ±0,3 mm | 100 up to 1 000 m | 0,071 kg/m |

| 19911 | 6,0 x 1,5 | ±0,3 mm | ±0,2 mm | 100 up to 1 000 m | 0,044 kg/m |

| 10189 | 6,0 x 2,0 | ±0,3 mm | ±0,3 mm | 100 m | 0,067 kg/m |

| 10190 | 7,5 x 2,0 | ±0,3 mm | ±0,3 mm | 100, 150 up to 1 000 m | 0,086 kg/m |

| 10192 | 8,0 x 2,0 | ±0,3 mm | ±0,3 mm | 100 m | 0,087 kg/m |

| 19912 | 9,0 x 1,5 | ±0,3 mm | ±0,2 mm | 100 up to 1 000 m | 0,068 kg/m |

| 10193 | 9,0 x 2,0 | ±0,4 mm | ±0,3 mm | 100 up to 1 000 m | 0,089 kg/m |

| 10194 | 9,5 x 2,0 | ±0,4 mm | ±0,3 mm | 100 up to 1 000 m | 0,094 kg/m |

| 10196 | 11,5 x 2,5 | ±0,4 mm | ±0,3 mm | 50, 60 up to 1 000 m | 0,148 kg/m |

| 14392 | 13,0 x 2,5 | ±0,4 mm | ±0,3 mm | 40, 50 m | 0,166 kg/m |

| 10203 | 14,5 x 3,0 | ±0,4 mm | ±0,3 mm | 50, 60 m | 0,244 kg/m |

| 20682 | 17,5 x 3,5 | ±0,6 mm | ±0,3 mm | 40 m | 0,344 kg/m |

| 10205 | 22,0 x 4,0 | ±0,8 mm | ±0,4 mm | 30, 40 m | 0,460 kg/m |

| 10206 | 25,0 x 4,0 | ±0,8 mm | ±0,4 mm | 20 m | 0,538 kg/m |

| 16129 | 32,0 x 5,0 | ±1,0 mm | ±0,5 mm | 20 m | 0,780 kg/m |

| 16133 | 40,0 x 5,0 | ±1,3 mm | ±0,5 mm | 10 m | 0,960 kg/m |

Delivery program and data sheet

Dateigröße: 45 KB